Why Aluminum Shop Castings Assistance Better Warm Dissipation in Industrial Equipment

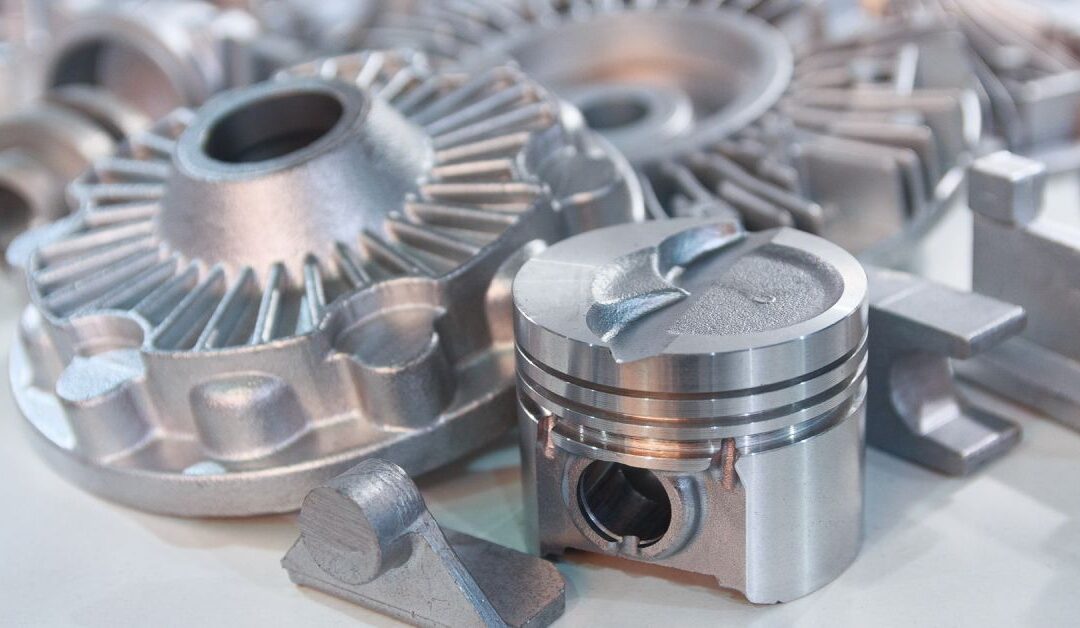

Light weight aluminum shop castings play an important role in enhancing warmth dissipation within industrial systems. Their extraordinary thermal conductivity allows for reliable warm transfer, while their light-weight nature improves functional effectiveness. Additionally, progressed casting strategies make it possible for intricate layouts that enhance thermal administration. These qualities collectively add to far better performance and energy cost savings. However, understanding the complete effect of these buildings requires a more detailed examination of their various applications and advantages in industrial settings.

Outstanding Thermal Conductivity of Aluminum

Light weight aluminum is renowned for its extraordinary thermal conductivity, making it a favored product in various applications. This property makes it possible for aluminum to efficiently transfer heat, which is necessary in markets that count on reliable warmth management. The high thermal conductivity of aluminum allows it to dissipate warm rapidly, lowering the risk of overheating in systems such as engines, electronics, and warm exchangers.

Furthermore, aluminum's thermal performance adds to enhanced performance and energy financial savings in several industrial procedures. When made use of in foundry spreadings, aluminum can be formed right into complex forms that boost warm dissipation additionally. This ability is particularly useful in applications calling for rapid air conditioning or temperature level policy.

Lightweight Nature of Aluminum Castings

The light-weight nature of aluminum castings uses considerable advantages across various industries, especially in applications where minimizing weight is crucial. This attribute improves functional efficiency, as lighter parts add to decrease energy consumption throughout transport and handling. In automobile production, for example, the decrease in general vehicle weight can lead to boosted fuel efficiency and improved efficiency. Similarly, in aerospace applications, the decrease in weight is crucial for achieving perfect trip efficiency and gas savings.

Improved Design Adaptability for Warmth Administration

Layout flexibility in warm administration is an important quality of aluminum spreadings that allows designers to optimize thermal performance in numerous applications. Aluminum Casting. The adaptability of light weight aluminum makes it possible for the production of complicated geometries and tailored layouts, which are crucial for efficient warm dissipation. This adaptability promotes the assimilation of air conditioning networks, fins, and various other features that boost thermal transfer in industrial systems

In addition, the capability to produce lightweight components without endangering architectural stability allows for cutting-edge styles that can efficiently manage heat in constrained rooms. By leveraging advanced spreading methods, designers can make improvements the thermal residential or commercial properties of aluminum spreadings to satisfy details operational demands. This level of modification not just improves efficiency yet also contributes to energy efficiency, ultimately causing minimized operational prices. By doing this, light weight aluminum castings act as a considerable source for sectors seeking improved heat administration options.

Resistance to Rust and Oxidation

Effective warm monitoring is usually tested by ecological variables, particularly deterioration and oxidation. Aluminum foundry castings display remarkable resistance to these concerns, making them an excellent option for commercial systems. The natural development of a safety oxide layer on aluminum surface areas assists protect against additionally deterioration, making certain the stability of components over time. This fundamental resistance enables light weight aluminum spreadings to maintain their thermal and structural residential properties even in rough atmospheres, where direct exposure to wetness, chemicals, and varying temperatures can cause considerable wear in various other products.

The light-weight nature of aluminum, incorporated with its rust resistance, contributes to the durability of industrial applications. This toughness reduces the frequency of replacements and upkeep, ultimately sustaining reliable heat dissipation. Aluminum factory spreadings are not only useful for their thermal buildings however also for their ability to withstand destructive and oxidative difficulties, making certain peak efficiency in demanding setups.

Cost-Effectiveness and Energy Effectiveness

The cost-effectiveness and power performance of aluminum foundry spreadings existing significant advantages for manufacturers. By lowering production costs and providing power savings, these spreadings represent a useful option for firms intending to maximize their procedures. Furthermore, the lasting financial investment worth connected with light weight aluminum castings enhances their allure in an open market.

Reduced Manufacturing Costs

While lots of sectors come to grips with increasing production prices, aluminum foundries have progressively turned to innovative methods to boost cost-effectiveness and power effectiveness. Making use of light weight aluminum for shop castings supplies substantial advantages, as it requires much less power to create compared to various other steels. In addition, aluminum's light-weight nature lowers transport prices and simplifies dealing with throughout manufacturing processes.

Using advanced casting strategies, such as die spreading and shed foam spreading, can further improve production and decrease waste. Metal Foundry. These contemporary techniques not just result in faster turnaround times but additionally enable for the reliable use resources. Light weight aluminum foundries are better placed to keep affordable pricing, eventually profiting markets reliant on high-quality castings for their procedures.

Power Financial Savings Benefits

Energy financial savings stand for a crucial benefit for aluminum shops, specifically in the context of cost-effectiveness and power performance. The lightweight nature of light weight aluminum permits lowered energy usage during manufacturing and transport processes. In addition, aluminum spreadings display exceptional thermal conductivity, enabling reliable heat dissipation in commercial systems. This efficiency lessens the requirement for extensive cooling mechanisms, bring about lower power costs over time. The resilience and durability of aluminum castings lower the frequency of replacements, this page adding to total power financial savings in production cycles. By integrating light weight aluminum shop spreadings, markets can attain substantial reductions in power expenditure while improving operational effectiveness, making it a critical selection for cost-conscious manufacturers looking for sustainable remedies.

Long-Term Financial Investment Value

Buying light weight aluminum foundry spreadings offers substantial lasting worth, particularly relating to cost-effectiveness and power effectiveness. These castings not just boost warmth dissipation yet likewise add to general system performance, leading to minimized functional expenses. The lightweight nature of aluminum permits simpler handling and transportation, reducing logistical expenses. On top of that, aluminum's sturdiness guarantees a much longer life expectancy, decreasing the need for constant substitutes. Reliable warmth management equates into reduced energy intake, which can considerably reduce utility costs over time. Furthermore, firms can take advantage of improved efficiency as systems run a lot more successfully. Inevitably, the initial financial investment in light weight aluminum foundry spreadings yields remarkable returns, making them a sensible selection for industries aiming to optimize performance while managing costs.

Applications of Light Weight Aluminum Shop Castings in Industry

Aluminum foundry castings play a pivotal role in various industrial applications because of their distinct residential properties, consisting of light-weight style and superb thermal conductivity. These spreadings are widely utilized in the vehicle market for engine blocks, transmission situations, and heat exchangers, where reliable heat dissipation is essential for performance and security. In the aerospace industry, light weight aluminum spreadings contribute to the decrease of aircraft weight, consequently enhancing gas effectiveness and total airplane performance. In addition, in the electronics market, aluminum spreadings are employed in warm enclosures and sinks, facilitating effective thermal management in tools. The versatility of light weight aluminum shop spreadings reaches manufacturing equipment parts, where longevity and resistance to rust are essential. In general, the applications of light weight aluminum foundry castings cover numerous markets, emphasizing their importance in advancing innovation and enhancing operational efficiency.

Frequently Asked Questions

How Do Aluminum Castings Compare to Various Other Materials for Heat Dissipation?

Aluminum castings normally outshine numerous other materials in warmth dissipation because of their exceptional thermal conductivity. Compared to steel or plastic, aluminum efficiently transfers heat, making it a favored option More Info for commercial applications requiring efficient thermal monitoring.

What Is the Life Expectancy of Light Weight Aluminum Factory Castings in Industrial Applications?

The life-span of light weight aluminum foundry castings in commercial applications usually varies from 10 to 30 years, depending on ecological conditions, maintenance, and functional anxieties, making them a sturdy selection for numerous industrial demands.

Exactly How Do Temperature Level Variations Affect Aluminum Casting Performance?

Temperature level variations can significantly influence aluminum casting performance, leading to thermal development or tightening. These fluctuations may create warping, anxiety cracks, or modified mechanical residential properties, inevitably influencing the toughness and dependability of the cast components in commercial applications.

Can Light Weight Aluminum Castings Be Recycled After Their Life Cycle?

Yes, aluminum castings can be reused after their life cycle. The recycling process preserves the steel's properties, check these guys out making it a lasting selection for numerous applications, thus minimizing waste and conserving sources in industrial procedures.

What Surface Therapies Enhance Light weight aluminum's Warm Dissipation Properties?

Surface area treatments such as anodizing, painting with thermally conductive finishings, and using warmth sinks significantly improve aluminum's warm dissipation homes. These approaches boost area and thermal conductivity, enhancing efficiency in various commercial applications.

Aluminum factory castings play an important duty in improving warmth dissipation within commercial systems. When used in factory spreadings, light weight aluminum can be molded into complex shapes that boost warmth dissipation even more. Layout versatility in warmth monitoring is an essential feature of aluminum castings that allows designers to maximize thermal performance in different applications. By leveraging advanced spreading methods, engineers can tweak the thermal properties of light weight aluminum spreadings to satisfy specific functional needs. Furthermore, aluminum spreadings exhibit exceptional thermal conductivity, allowing reliable heat dissipation in commercial systems.